Background

An extended-research project according to my thesis

In 2020 when I was doing my second-year master study of cultural materials conservation, COVID-19 arose and the situation looked not positive. Pandemic level with lockdown in Melbourne meant that I could only do a research-based thesis without the ability to access the lab to do practical-based research. Also, students could not access the library to borrow books, so references were only accessed online, such as academic journals, e-books, or YouTube videos. It was a challenging period and undertook the thesis project during the strictest restrictions and lockdown. These limitations made me unable to conduct testing on different surface coating materials for comparison. Even at those challenging moments, I could not purchase some resources from overseas because the border had been closed. Delivery was delayed, and I also have budget issues that require creativity.

AICCM Mentorship Program 2020

I saw this mentorship announcement and thought I could put this idea into place with the program once I finished my thesis. Luckily I met a great mentor, Jennifer Loubser, a specialist conservator of East Asian paintings at Studio 204 Brisbane, and previously at Honolulu Museum of Arts, East Asian Paintings conservation department since 2005. She has also worked as a Paper Conservator at the State Library of Queensland since 2014, and ran a Karibari workshop there with her mentor. We had lots of conversations to discuss our thoughts and her experience in karibari boards. After an initial phone call, I set up fortnightly Zoom meetings to update my progress, stay in communication, ask any questions I came across, and receive my mentor’s feedback. I enjoyed these sessions of communication because I continued my learning from my interests and specialisation. I appreciated this opportunity and the people I’ve met in this program.

Project timing and timeline

This program is a three-month commitment actually I commenced at the beginning of 2021 after my master graduation from the University of Melbourne. I planned my schedule for 2021, and I think I can do this manufacturing project from summer to autumn (weather issue when applying the fermented persimmon juice). Meanwhile, I commenced my full-time half-year study for the Diploma of Leadership and Management at Victoria University. It is a business course. The main purpose is to support the students in gaining confidence with leadership and management, building relationships at the workplace with your team, how to facilitate your team, planning such as operational plan, strategic plan, reviewing the organisation policy, recruitment management, etc.

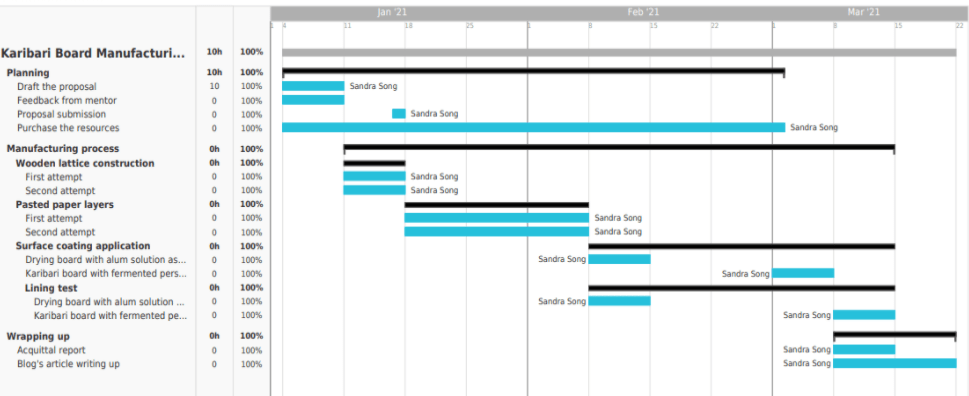

Below is a Gantt chart that I had learnt from my Diploma course, and I think it has helped to present my karibari schedule planning.

Luckily I found a reliable supplier who can be involved in my networking and also thanks to my native language it was easier to build trust and a relationship with my supplier. I can say it is still challenging for me to connect with suppliers but I am working toward my outcome. No matter how the COVID pandemic is, I can slowly make progress within the timeframe I set.

I also communicated with my supplier by using Line. Fu Lung Cotton Paper Co. Ltd Is the supplier I approached and I’ve been very satisfied with their service. I tried to approach a Japanese supplier but I cannot write a Japanese email so I wrote in English instead and it seems the communication had been lost. Maybe I will try next time without the time frame limitation.

Project Aim

Construct a sample-sized (600 x 600 mm) karibari board by following the instructions from Webber, Huxtable (1985), and Fraser (1988) to investigate its manufacturing process. During this project, I constructed a sample-sized karibari board by following the instructions from Webber, Huxtable (1985), and Fraser (1988) to investigate the manufacturing process. It was a practical-based project which extended from the author’s thesis (Song 2020) and commenced at a home-based working station in January 2021, lasting three months. The manufacturing process included constructing a wooden lattice, pasted paper layers, and surface coatings (i.e. alum solution and fermented persimmon juice).

Project Process

Communication Channels

After the initial phone call from my mentor, I set up a Zoom meeting fortnightly to report and update my progress and share information. I have enjoyed these conversations because we shared our thoughts in our professional areas and learnt from each others’ experiences. Jennifer suggested we post the kozo papers that we had used for karibari layers which can help me know more about some different types of kozo.

Regarding the details of manufacture of pasted paper layers and level of waterproof of surface coating, Ika Hsiao (Associate conservator of Chinese paintings at Cleveland Museum of Art since 2014) is the specialist conservator of East Asian paintings who presented her manufacturing experience via one Zoom meeting session, and updated my progress via Line.

Tools and Resources Preparation

- Woodwork stage

Hand saw, drill, clamps, rules, file (or sand paper), weights, and pine wood strips. A stable table surface when constructing the board. I prepared and built the wooden lattice in the backyard to avoid dust issues and used a mask as needed.

- Pasted paper layers stage

Kozo (mulberry) paper in different types of thickness, different brushes (pasting brush and smoothing brush), spray, wet and dry towels, wheat starch paste, sieve, and containers to place the paste.

- Brush for the coating layer

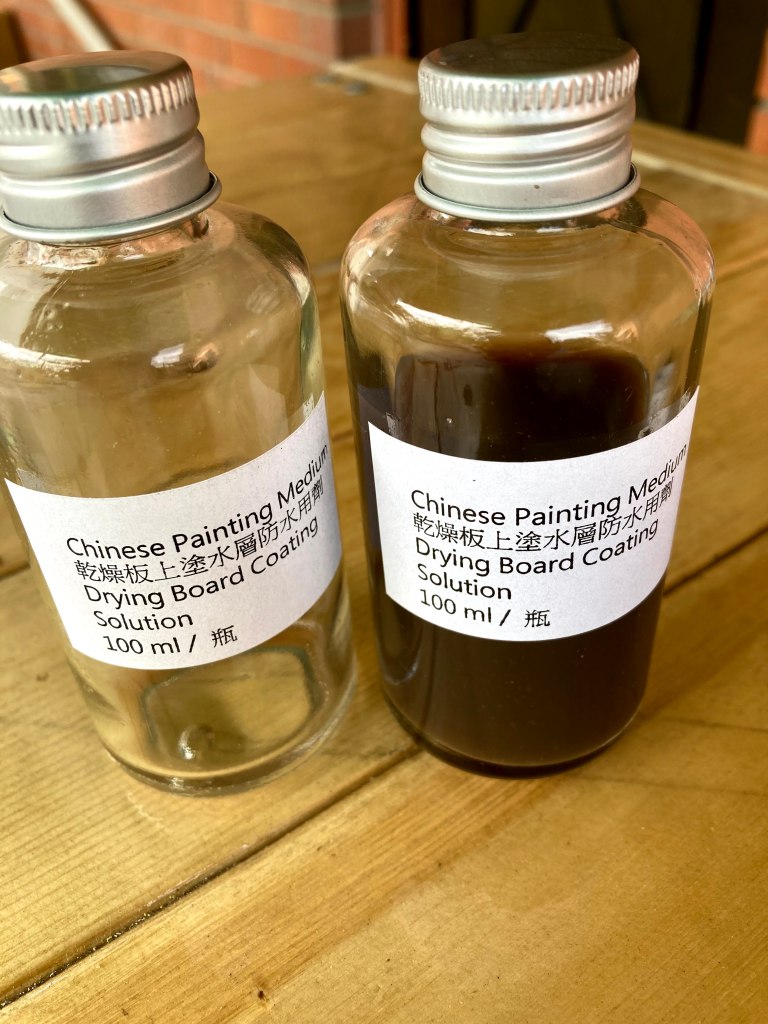

Brush, container and coating materials (alum solution and fermented persimmon juice).

Knowledge and Skills Preparation

Knowledge of karibari board is from my one-year research project (conservation minor thesis at the University of Melbourne) and consultation with some professional and experienced conservators, including Ika Hsiao during the initial approach in 2020. Skills like brushing and pasting skills, which I learnt from the 1-year subject of Chinese Mounting ten years ago when studying my Bachelors. I am so grateful to have studied for my Bachelors degree in Art History at the Tainan National University of Arts, even though it is a very rural place. It is a course teaching art history, museum studies, and conservation. After two years students can choose a pathway and specialisation. After I chose conservation, I selected paper conservation instead of Asian paintings and objects. During this two-year training, I learnt what conservation and preventive conservation are, how to write condition reports, materials history, one year of basic chemistry, and practical subjects such as Japanese gold leaf decoration technique + Eastern Gouache (nihonga), ink painting, bookbinding, Chinese Mounting, calligraphy, watercolour painting, and sketching. It is an excellent place for learning foundational knowledge and skills before the master study.

Karibari Manufacturing Process

- Wooden lattice construction

- Pasted paper layers

- Coating layer application

A Timelapse video embedded to show the application of surface coating with the fermented persimmon juice in my backyard.

- Lining test

Project Outcome

To make sure the drying board can work functionally, a waterproof test by applying a water drop to see the drying speed and the penetrating rate and lining test applied. Below is a table to summarise the result of the test.

| Karibari board with fermented persimmon juice as a surface coating | Drying board with alum solution as a surface coating | |

| The level of waterproof, see drying speed when testing by a water drop | Very slow drying speed and water drop has penetrated the board | Very slow drying speed and water drop has penetrated the board |

| Lining testing (if satisfied with work functions) | Satisfied (dry with flattening) | Satisfied (dry with flattening) |

The project outcome is satisfied, and both these drying boards (no matter in Japanese or Chinese style) can be used for drying and flattening application in conservation treatment although limited in size.

Justification: decision-making for the final coating layer application

Through decision-making for the final coating layer application, I consulted with my mentors consistently when commencing the project. The challenge of deciding between my two preferred coatings was resolved when I decided to make two boards and purchase two coating materials (i.e. alum solution and fermented persimmon juice). Due to COVID, there are not many suppliers that can be sought. There are potential health and safety concerns, overseas shipping delays and the temporary stop of overseas shipping service that needs to be considered. I appreciate the supplier who is happy to send materials through.

What’s Next

There may be other coating materials that can be applied to the surface of the drying board. I haven’t had a chance to apply the conservation products such as Paraloid® B72 and RhoplexTM emulsion, the commercial products like floor finish, varnish, and Tung oil, or even the natural adhesive like shellac. Many adhesive materials have the same characters and they may have the potential surface coating if they don’t have any harmful substances transferring to the object which is applied on the drying board.

Home-based work station and limited budget scale down the project but so far I am satisfied with these attempts. I am so happy that I have drying boards with me and they can be my tools for doing lining practice and flattening and drying paper. I have four Japanese silk paintings that may be my next project, but before commencing I need to set up my working environment which is just a simple workstation.

After this project, I will spend time on my family commitments because obviously I work on weekends for my project and assignments. Any comments and feedback please feel free to leave below, I appreciate your thoughts.

Acknowledgement

I appreciate my mentor, Jennifer Loubser and the AICCM Mentorship Program supporting me to undertake this Karibari Board Manufacturing Project. It is an unpaid project that my mentor contributes her time discussing with me. I spent my Jobseeker payment from Centrelink to purchase the resources which I needed to complete this project. Furthermore, I would like to thank Ika Hsiao and her karibari board manufacturing knowledge which I don’t feel I only do by myself. Also, some of my friends in Australia, Taiwan, and the US (in conservation and other fields) follow with interest in my project. I appreciate you all and my family’s support to tolerate the strong smell of fermented persimmon juice coating application.

References

AICCM 2020, AICCM Mentorship Program, Australian Institute for the Conservation of Cultural Material, viewed 21 December 2020, < https://aiccm.org.au/membership/student-membership/mentorship-program/?fbclid=IwAR2YRPsTaE4CKuQqnODwu12JWityx4AbNWZXX8xPRWRBt0FClEupir3dmgQ>.

Fu Lung Cotton Paper Co. Ltd, Fu Lung Cotton Paper calligraphy supplies, Fu Lung Cotton Paper Co. Ltd, viewed 14 July 2020, <http://www.calligraphy.url.tw/content.php?cn=item&cid=52>.

Song, S 2020, ‘Investigating KARIBARI, the drying boards and their materials used’, GCCMC unpublished minor thesis, The University of Melbourne, Melbourne.

Smithsonian’s National Museum of Asian Art 2018, Making a Traditional Chinese Drying Wall, video, YouTube, 3 October, viewed 29 July 2020, <https://www.youtube.com/watch?v=8Rg12UXatZ0&feature=youtu.be&fbclid=IwAR0TjB10TKTFNpJaqBFXdGMEFeaftlgOsdRoEO1Bz6vxgEEGQ4TtPAL4HeA>.

The Folger Shakespeare Library 2014, Making a Karibari Board, video, YouTube, 2 May, viewed 11 May 2020, <https://www.youtube.com/watch?v=0rKNd2a_S5s&list=UUBOl-Rnudd-b0XJsmKDId-g>.

Further Links You May Be Interested

Blog articles from Jennifer Loubser

Recent blog article Jennifer Loubser wrote about how she has been using the karibari with the State Library’s original art collections lately.

https://www.slq.qld.gov.au/blog/gift-keeps-giving-generous-progress-karibari-board-workshop

Ika Hsiao’s podcast: Mustard Seed Art Conservation Studio

A series of podcasts for discussion of conservation and life experiences in Mandarin.